Cooperators

Industry Cooperators

Ultra Petroleum, Shell Rocky Mountain Production, and Questar own 90% of the leases in the Pinedale Anticline.

|

Boulder Air Quality

This air quality monitoring station was installed in 2005. It monitors air quality leaving the Pinedale Anticline. It monitors visibility, ozone, NOx, particulates, and weather data. The Wyoming Department of Environmental Quality maintains the station. Data is available online.

|

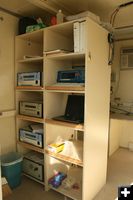

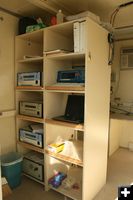

Monitors

Air quality monitors inside the Boulder monitoring station. Equipment monitors ozone, NOx, particulates, visibility, ammonia, solar radiation reflection, and weather conditions. In the winter, hydrocarbon monitoring studies are also being done. The Wyoming Department of Environmental Quality monitors and validates the data. This station is just one of a network of air quality monitoring stations set up around the Upper Green River Basin actively monitoring local air quality and gathering baseline data.

|

Visibility webcam

The Boulder Air Quality Monitoring station has two webcams to monitor visibility. Images are posted online on the Wyoming Department of Environmental Quality website, www.wyvisnet.com.

|

Solar Radiation Monitoring

This device measures incoming and outgoing solar radiation. Winter ozone occurrences appear to be related to a multiplying effect of solar radiation reflected off snow-covered ground.

|

Questar Liquid Gathering System

Questar has three LGS facilities in the Pinedale Anticline. Shell and Ultra will have their LGS stations operational by September, 2010. The purpose is to use pipelines to carry the natural gas, condensate and water liquids to reduce truck traffic. Once all the companies have their LGS systems operational, they will eliminate 165,000 truck trips per year that used to be required to service well sites in the Pinedale Anticline.

|

Separater

Kevin Williams, Pinedale District Manager for Questar, shows where the natural gas, water and condensate that come from a wells are separated. Gas and condensate are commerical products. The water is recycled and used in drilling operations. All three are pumped into a liquids gathering system pipeline for transportation to their respective processing areas.

|

Control Station

Questar's Kevin Williams explains that the entire Liquids Gathering System can be monitored from an onsite control station, as well as remotely, with real time status information. Natural gas and condensate are marketable products. Most of the water is recycled back for reuse in system operations. Some of the companies are disposing of their used water by putting it back into the ground in reinjection wells.

|

Separation Lines

The gas, condensate and water are separated out and transported via pipelines for further processing.

|

Pressure Gauge

Monitoring pressure is an important part of the process. Drops in pressure can indicate a leak in the system. All equipment stations are visited regularly and monitored very closely.

|

Well Pad

The Pinedale Anticline natural gas field is expected to have a productive lifespan of approximately 40 to 50 years. Once over, surface equipment will be removed and the land will be reclaimed to look very much like it did before the activity began. Wellpads will shrink to about 50 feet, reseeded with native vegetation, and a two-track road leading into the wellpad site.

|

Drilling

Once drilling is completed, the drill rig goes away. In 2005, one straight-down wellpad took more than 8 acres. Today, with directional drilling, dozens of wells can be clustered onto a single wellpad, significantly reducing the surface disturbance per acre taken by each well.

|

SCR Devices

This photo shows three Johnson Matthey emissions control systems installed on top of three caterpillar diesel engines on a Shell drill rig in the Pinedale Anticline. These devices eliminate 90-95% NOx emissions from the diesel drill rig engines. Shell has installed these devices on all their drill rigs. Diesel engines outfitted with these devices emit less NOx than natural gas drill rig engines, said Jim Sewell, Environmental Engineer for Shell. Photo courtesy Johnson Matthey.

|

Berms

Well pad equipment is surrounded by berms to prevent any potential spills from entering surface water pathways.

|

Buried pipelines

A tremendous network of pipelines and cables are buried underground, protected from the weather and hidden from view. Surface disturbance is reseeded. In a few years, the surface revegetates and blends in with the adjacent undisturbed areas.

|

Single Well

This is an old, straight-down, single gas well. Now companies can place multiple wells on a single pad and use directional drilling to tap gas pockets more than 1/4 miles away and 14,500 feet deep. Directional drilling and clustering wells helps minimize surface disturbance of the land, which is important because the Pinedale Anticline area is also wildlife habitat for deer, antelope, sage grouse and other species.

|

Sublink Stage

Some of the companies use Sublink Stage to carpool transport employees to and from their worksites, which helps reduce vehicle traffic on nearby roads and improves safety in logistics of the workforce.

|

Water well

Industrial water wells are used to provide water for drilling activity. These wells are much deeper than drinking water wells, and the water is typically not fit for human or livestock consumption. The water quality is monitored regularly by the Sublette County Conservation District.

|

Backflow preventers

Industrial water wells are now outfitted with double backflow preventers (the blue double caps), which prevent contaminants from the trucks drawing water flowing back into the well. If pumps are moved, they are steam cleaned before being placed in a new well.

|

Rehabilitation

This site was rehabilitated four years ago, planted with sagebrush, hardy native grasses and forbs. Plants are adapted to the natural rainfall for their moisture requirements.

|

Lek Road

The BLM closed this portion of the road because of the presence of a sage grouse lek (mating area). The road now goes around the lek and rejoins the road off in the distance.

|